The CLEAN project (Catalytic Low-temp Efficiency for Advanced decontaminatioN), led by Bert Weckhuysen, has been awarded €1.5 million in funding from the Rijksdienst voor Ondernemend Nederland (RVO).

The CLEAN project addresses one of the most pressing environmental challenges of our time: the inefficiency of current plastic recycling methods. Traditional pyrolysis processes operate at temperatures up to 800°C, resulting in high energy consumption, low selectivity, and significant CO2 emissions. CLEAN aims to develop novel low-temperature catalysts that enhance both energy efficiency and product quality, attaining low-temperature processes.

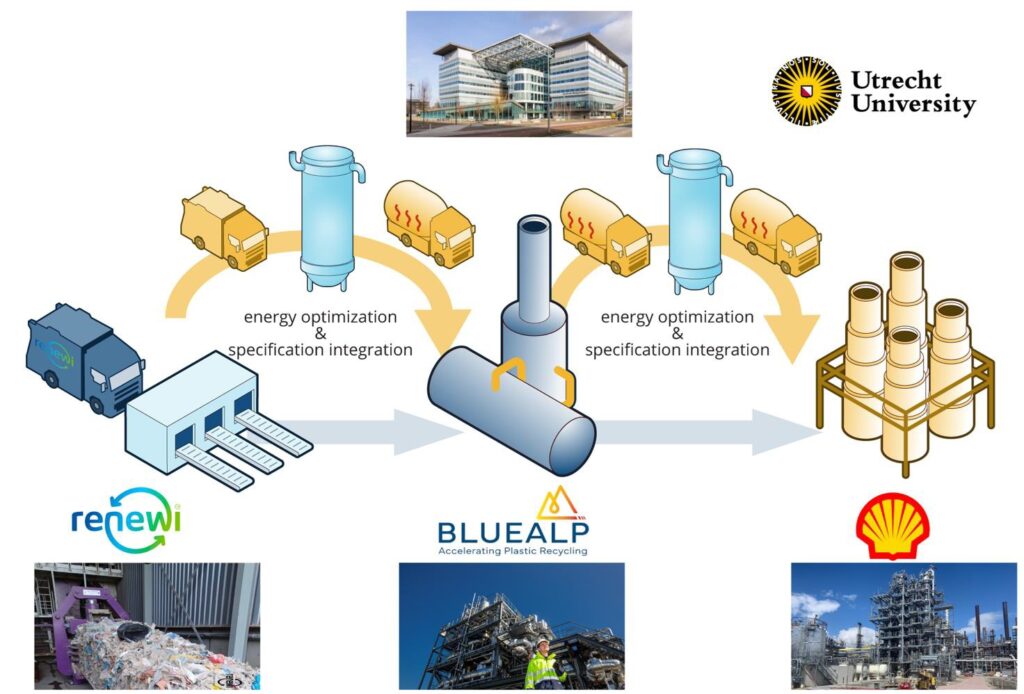

Led by Bert Weckhuysen’s Inorganic Chemistry and Catalysis group at Utrecht University, the project brings together key players from across the entire plastic waste recycling value chain:

- Utrecht University – Leading research in catalyst and adsorbent development

- Renewi – Providing expertise in plastic waste collection, sorting, and densification

- BlueAlp – Contributing thermal pyrolysis technology to convert plastic waste into pyrolysis oil

- Shell – Serving as the end-user, converting pyrolysis oil into valuable chemicals

This comprehensive partnership ensures that every step of the recycling process is optimized, from initial waste collection to the final step, the production of chemicals.

The project specifically targets polyolefin films, developing adsorbents and catalysts capable of:

- Dewatering and decontaminating real-life plastic waste

- Operating at lower temperatures for improved energy efficiency

- Producing higher-quality pyrolysis oil suitable for chemical production

- Reducing the overall CO2 footprint of the recycling process

The research will be conducted by a dedicated team including a PhD student, technician, and postdoctoral researcher, who will work both in laboratory settings and on-site with industry partners to ensure real-world applicability.

The project represents a significant step forward in making chemical recycling of plastics more sustainable, efficient, and commercially viable, contributing to the circular economy and reducing the environmental impact of plastic waste.

For more information about the CLEAN project, visit the RVO project database and CircularPlasticsNL news item.