Plastic: chicken or egg of the waste cycle – That’s the topic Prof. Bert Weckhuysen (chair, UU), Jaap den Doelder ( TU/e), Ina Vollmer (UU) and Lonneke Slenders (Ioniqa) will discussed during the MCEC Focus Session at CHAINS 2020. On this occasion, we asked Ina Vollmer about her views on this matter.

How could we deal with plastic waste?

I think that the plastic waste problem can only be solved in a concerted effort. It is crucial to attack it from many different directions, addressing every link in the value chain and making sure those links work together.

What challenges do you see in the value chain?

On a consumer level, new concepts for reuse like refilling stations for shampoo bottles or bulk stores have to be found.

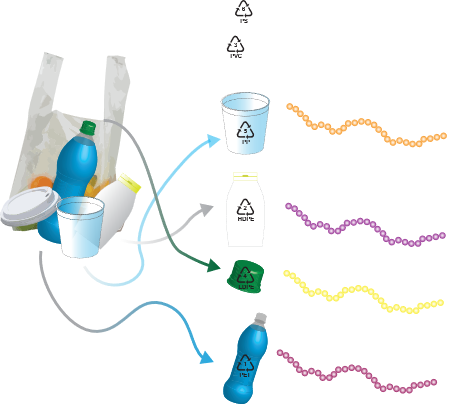

Of course, plastic sorting methodologies also have to be improved. Mechanical recycling or melting and re-extrusion need to be improved as well and used as much as possible. But at the moment mechanical recycling usually yields a lower quality product (chemical-recycling.nl). Therefore, chemical recycling can address a wider variety of plastic waste streams and yield various different, more pure products (review article).

Here I see these major challenges:

- Catalyst development to obtain desired molecules with higher selectivity

- Dealing with waste consisting of more than one polymer or that contains contamination like food waste

- Removing polymer additives

- Lowering energy demands of these recycling technologies

However, these advances should go hand-in-hand with developments in other fields like the design of new monomers and corresponding polymers that can more easily be depolymerized back to monomers. In addition, the development of additives that are more easy to remove and recover would be beneficial.

What is your research about?

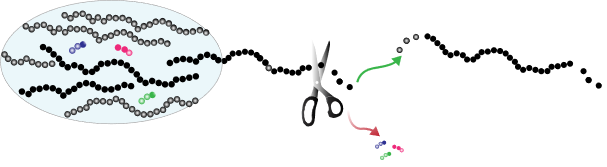

We are mainly working on point 1 and are focusing on polymers with a high production volume, mainly polyolefins. Polyolefins make up almost 50% of our plastic demand in Europe. The chemical bonds in polyolefins are harder to break than the bonds of other polymers, like polyesters or polystyrene and therefore energy requirements are high. In addition, selectivity to desired products is hard to achieve.

We want to produce interesting feedstock for the refining industry like BTX and monomers (ethylene, propylene) but we also want to find ways to make value-added molecules.

We are quite at the start of all of it, which is very exciting. Having worked on it for about a year and a half, we are currently understanding the mechanism of catalytic breakdown of plastics. Especially, when using ECAT. This so-called equilibrium catalyst is very interesting to use as it is itself a waste catalyst from the refinery and seems to work even better than the fresh catalyst when it comes to plastics.

Do you think we will see a solution in our lifetime?

I can feel that things are starting to stir with commitments from big companies to work on it, new companies founded and more funding available. In the end, however, it will all come down to proper lawmaking. Recycled plastics need to become economically competitive and this will only happen if the environmental costs of plastic production from crude oil are incorporated in the price. This could for example be achieved with a tax on greenhouse gas emissions.

Source: website MCEC